PRODUCT CENTER

- 产品 · 中心 -

|

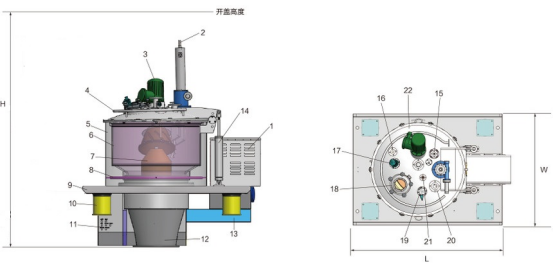

PLD拉袋式刮刀全自动下卸料离心机

收藏

PLD Automatic self-cleaning bottom discharge centrifuge,discharges by small scraper,operates intermittently.lt automatically completes feeding,separating,discharging and cleaning with in work cycle according to different requirements.PLD series centrifuge adopts HMI and PLC,working accompanies with converter,machinery automatic discharging unit,overload automatic detection unit and valves,to realizes automatic operation of whole machine set.It is suit for separation of solid suspension includes tiny and medium particles,also suit for separation of fibrous material.Application field:chemical industry,food industry,pharmaceutical industry,mining industry and environmental protection industry,etc.

Working principle Material comes into roating drum trough feed tube,centrifugal force field makes it spread evenly on filter cloth of interior wall.During separation process,liquid trough gap within solid phase and filter cloth also holes of drum interior wall,discharges by outlet.While solid material retained within drum wall.After separation,scraper cuts filter cake into pieces,then discharges by outlet.The last step is self-cleaning,remove solid residues.

Main features Machine to follow the industrial design the concept of "system integration, cross-border integration", comprehensive functional,practical, security system design, while meet the equipment performance, strengthen equipment operability and maintainability, to ensure the efficient and stable, safe, truly add value for the user.

Safe for use A. Main shaft bearing safety running 1) Optimize main shaft bearing structure,assembly and dis-assembly both simply and reliable,ensure safe usage of bearing. 2) Centralized lubrication of grease. Main bearing separately supply grease to upper unit and lower unit by high pressure,downgrade of on site maintenance difficulty. B.Liquid material safely spread within drum Distribution method: Blade wind wheel rotative distribution 1) Relieve attrition caused by liquid disorder. 2)Remove distribution blockage and unevenly distribution made by liquid pressure wall nearby outlet. 3) Reduce the time of material stays within distributor,evenly distribution. 4) Relieve unusual vibration of equipment,protect accessories and components. C.Residues safety Residues removal: lever type automatically remove residues on filter bag. In operate state, filter bag adhesive to drum interior wall; in non-operate state,filter bag deforms under the effect of connecting rod (become a 60 degree circular cone concentric with main shaft),remove residues on filter cloth and discharge by outlet. 1) Connecting rod has a simple structure and reliable function. 2) Improved separation effectiveness. 3) Effectively remove residues,protect material from cross infection. D. Operation safety Unique design ensure safety of on site personnel and equipment running. 1) External manual oil pump, facilitate on site personnel to operation,ensure on-duty maintenance for main shaft bearing,reduce failure rate meanwhile promote production efficiency. 2) High pressure oil pipeline and circuit designed within shield,interfaces are laid together.Clean and tidy,ensure safety of human and equipment. 3)Adopt HMI and PLC,unattended operation,automatically monitoring and protecting.

1、Motor components 2、Blade components 3、Inclined disk distribution device 4、CIP online clearing 5、Machine housing 6、Drum sub-assembly 7、Transmission unit 8、On-line cleaning under CIP 9、Frame sub-assembly 10、Damping shock absorber 11、Integrated wiring port 12、Dump hopper 13、Belt cover 14、Open-cap cylinder 15、Atomizing scrubber 16、Drain port 17、Explosion-proof lamp 18、Manhole mirror 19、Material level detecting device 20、Exhaust pipe 21、Nitrogen filling port 22、Flap sub-assembly Technical parameters

|